Training Courses

-

Read More

Training Schedule & Registration Form

Below, you will find listings of all of our classes and schedules. You may register online using our registration form on this page. Please make check payable to: Brunson Instrument Company. For your convenience we have hotel information, maps, and directions to our Kansas

-

Read More

Field Calibration & Adjustment

Benefits Of Understanding Field Calibration & Adjustment

Is my instrument calibrated? That’s th

e question every end user asks as they make critical path decisions based on their measured data. Our field calibration course not only answers this question, but provides technicians with the skills needed to correct instrument errors right where it counts the most – on the jobsite.

e question every end user asks as they make critical path decisions based on their measured data. Our field calibration course not only answers this question, but provides technicians with the skills needed to correct instrument errors right where it counts the most – on the jobsite.Whether your cal lab is across the street or across the country, sending an instrument out for calibration during a critical path outage is an expensive, time-consuming proposition. Learn to evaluate instrument calibration immediately to determine if project discrepancies are instrument- or hardware-related.

-

Read More

Calibration & Adjustment

Optical Tooling Calibration & Adjustment

Benefits Of Understanding Calibration & Adjustment

Is my instrument calibrated? That’s the question every end user asks as they make critical path decisions based on their measured data. Our calibration course not only answers this question, but provides technicians with the skills needed to certify those instruments – an important consideration in today’s quality minded business environment. Minimize turnaround times and the expenses that go with calibration outsourcing. Qualify the equipment in a certified lab or right on the job site. Troubleshoot instrument questions immediately to determine if project discrepancies are instrument- or hardware-related.

Is my instrument calibrated? That’s the question every end user asks as they make critical path decisions based on their measured data. Our calibration course not only answers this question, but provides technicians with the skills needed to certify those instruments – an important consideration in today’s quality minded business environment. Minimize turnaround times and the expenses that go with calibration outsourcing. Qualify the equipment in a certified lab or right on the job site. Troubleshoot instrument questions immediately to determine if project discrepancies are instrument- or hardware-related.Your knowledge of instrument calibrations will

-

Read More

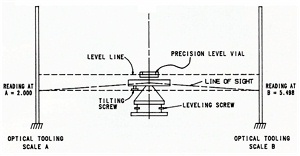

Optical Tooling Theory & Applications

Benefits Of Optical Tooling

Employ optical alignment procedures to enhance productivity and performance, and to decrease down time during maintenance and equipment installations. Control vibrations of critical rotational components to help maximize machine life. Increase production speeds without compromising product quality. Inspect fixtures and final assemblies for dimensional accuracy. Incorporate optical measurement with a preventative/predictive maintenance program to monitor manufacturing processes.

Employ optical alignment procedures to enhance productivity and performance, and to decrease down time during maintenance and equipment installations. Control vibrations of critical rotational components to help maximize machine life. Increase production speeds without compromising product quality. Inspect fixtures and final assemblies for dimensional accuracy. Incorporate optical measurement with a preventative/predictive maintenance program to monitor manufacturing processes.Learning Objectives

Become familiar with principles of light and optics, and how they work in various optical devices. Know how to operate each optical tooling instrument and what measurements each will